Why Smart Grain Dryer Monitoring Systems Are Key to Sustainability

As global demand for high-quality grains continues to surge, the need for innovative, efficient, and sustainable storage practices has never been more urgent. Farmers and grain storage managers are increasingly recognizing that grain quality doesn’t just depend on what happens in the field—it hinges on what occurs after harvest. The moment grains are stored, their quality begins to deteriorate, and without proper management, the value of the product can decline significantly. Moisture levels, in particular, are among the most critical factors influencing grain longevity and marketability.

Proper moisture control isn’t just a matter of preference; it’s a necessity. And the methods we use to manage it are evolving rapidly. Just a few years ago, monitoring grain moisture involved guesswork and inconsistent results. Today, however, modern grain dryer monitoring systems are transforming how we store and protect our grains—helping us preserve product integrity, minimize waste, and promote long-term sustainability.

We need to focus on essential industry tools and factors, including methods for measuring grain moisture, the application of moisture sensors in grain storage, and the importance of precision and reliability in these processes. These technologies are laying the groundwork for advanced grain management, enabling us to make improved and quicker decisions that safeguard our harvests and enhance our profitability.

Transforming Grain Storage with Technology

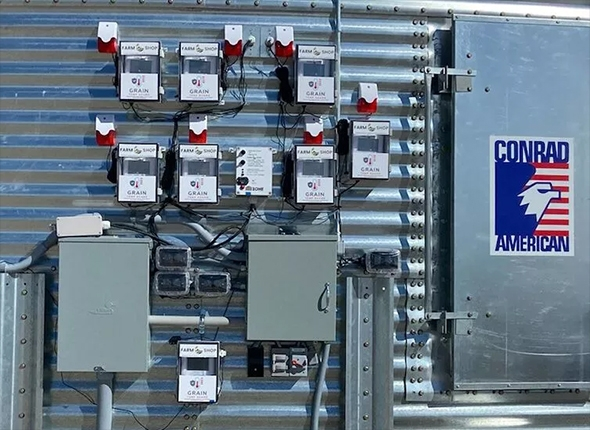

One of the most impactful advancements in grain storage has been the development of automated monitoring systems. These systems eliminate the guesswork by delivering real-time data on moisture content and temperature. Instead of relying on manual checks or visual cues, we now utilize precise measurements, ensuring uniform drying and safe storage across all bins.

At FarmShop MFG, we understand that the ability to measure moisture accurately and consistently isn’t optional—it’s the bedrock of grain preservation. Our cutting-edge technologies are designed to enhance storage operations while reducing environmental impact. By integrating innovative systems that alert us when moisture levels deviate, we can take immediate action and prevent loss before it occurs.

The Importance of Precision in Moisture Control

Precision is critical when it comes to grain moisture. Even slight fluctuations can trigger spoilage, sprouting, or fungal growth. That’s why leveraging the use of a moisture sensor is vital. These sensors provide continual updates and enable automated adjustments to maintain ideal drying conditions.

Moreover, the level of consistency in our readings directly determines the outcome. It’s no longer acceptable to rely on broad estimates. Instead, data-driven systems ensure we manage each batch of grain with confidence—helping us maintain quality, comply with safety standards, and meet market expectations without compromise.

Integrating Sustainability Through Smart Systems

Sustainability is no longer a trend; it’s an imperative. With energy-efficient designs, modern grain dryer monitoring systems enable us to reduce energy consumption without compromising quality. By eliminating the need for repeated manual checks and enabling predictive adjustments based on weather data, these systems make our operations more agile and environmentally responsible.

Through better data, lower energy use, and more dependable results, these systems don’t just support our current needs—they set us up for long-term resilience in a changing climate.

The Road Ahead: Smarter Decisions for a Smarter Future

As we look to the future, the question is no longer whether to upgrade, but how quickly we can adopt the technologies that are already reshaping our industry. Learning how to use measure grain moisture properly is no longer reserved for the technically inclined—it’s becoming standard practice across progressive farms.

When we prioritize accurate monitoring and invest in intelligent systems, we’re not only protecting our harvest—we’re future-proofing our entire operation. Systems that were once optional luxuries are now essential tools in our effort to maintain grain quality, reduce waste, and meet rising global demand.

Conclusion: Building a Sustainable, Profitable Future

To maintain the highest standards in grain storage, we must fully leverage the capabilities of modern monitoring. The use of a moisture sensor for grain offers precision, while accuracy and consistency in moisture readings ensure the lasting quality of the grain. And by integrating a reliable grain dryer monitoring system, we position ourselves to lead in both efficiency and sustainability.

Ready to take the next step toward smarter storage? Contact us today to learn how we can help you transform your grain storage system for a more sustainable future.